不同外径的焊管,磁棒和线圈处于什么位置是最理想的

What are the ideal positions for a coil and impeder for various tube sizes?

The position of the coil is usually dictated by the design and size of the weld roll assembly. For maximum

weld efficiency, the coil should be as close as possible to the weld point. In practical terms, this is usually

about equal to the radius of the squeeze rolls. The coil will heat the rolls and support structure if it is too

close, so it should be far enough way to minimize this.

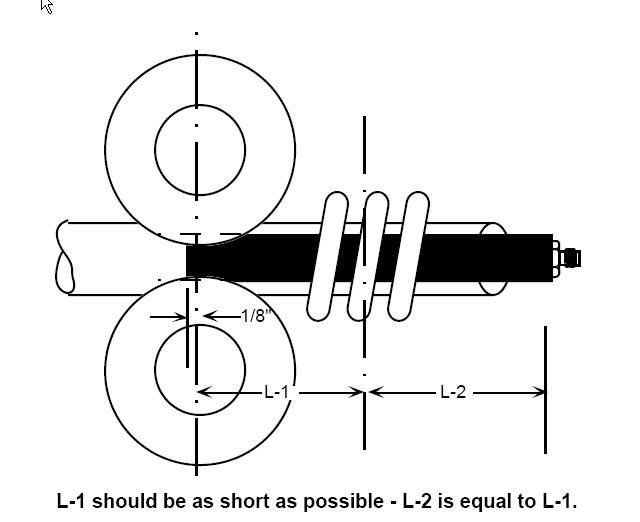

Impeders should be positioned so that the end of the ferrite is just beyond the weld point. (See diagram on

the following page.) Extending the ferrite too far down the tube has no adverse effect, but having it too short

will cause a dramatic reduction in weld speed. The length of the ferrite should be sufficient that it extends

beyond the coil for the same distance upstream and downstream.

Impeders are usually positioned close to the centerline of the tube. There is a small gain in efficiency if the

ferrite is above centerline, as close as possible to the edges of the strip, but it is more vulnerable to heat and

mechanical damage in this position.

|

|Archiver|手机版|钢管动力 官网

( 沪ICP备08002050号-3 )

|Archiver|手机版|钢管动力 官网

( 沪ICP备08002050号-3 )